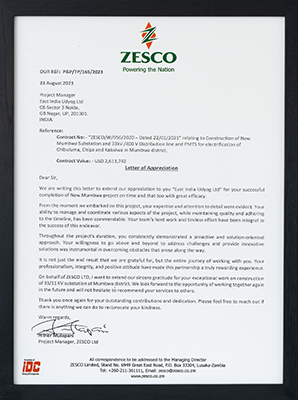

Letter of Appreciation on behalf of ZESCO LTD. for expectational work on substation of 33/11 KV substation at mumbwa district, Zambia.

Certifications

Letter of Appreciation on behalf of ZESCO LTD. for expectational work on substation of 33/11 KV substation at mumbwa district, Zambia.

Certifications

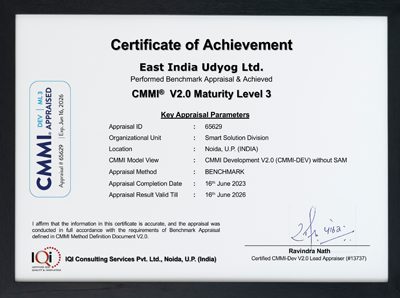

Performance Benchmark Appraisal & Achievement certification, CMMI V 2.0 Maturity Level 3

Pioneer as a single stop destination for urban infrastructure, water management, smart cities, and construction needs, all powered by cutting-edge digital innovations.

Certifications

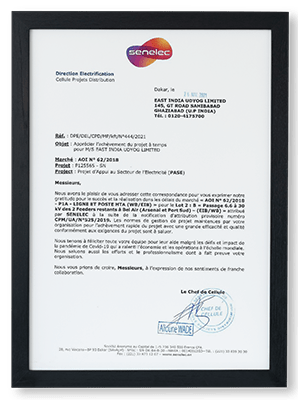

Letter of Appreciation by SENELEC, Senegal for on time Completion of project.